Sustainable Maintenance

Safe Industry

Future Production

Skilled Maintenance

SUSTAINABLE MAINTENANCE

Building an industry that lasts

What role does maintenance play in building a more sustainable industry? It’s not just about fixing what’s broken, it’s about working smarter and thinking long-term. By investing in preventive maintenance and fully leveraging the potential of digitalization and emerging technologies, we can reduce waste, extend equipment lifespans, and create safer, more efficient workplaces. This is how we build an industry that’s not only profitable today but also built to last.

Want to learn how to cut waste, optimize resources, and develop a more sustainable maintenance strategy? Through sessions on smart maintenance, predictive technologies, the circular economy, and digital transformation, you'll gain valuable insights into the innovations shaping a more resilient and responsible industrial future – Join us at Sustainable Maintenance during Underhåll 2026.

SAFE INDUSTRY

A symbiosis between human and machine

In today’s industrial landscape, safety is non-negotiable. But how do we create workplaces where people feel secure and can focus on what they do best? It starts with minimizing the risk of accidents, promoting a healthy work environment, and investing in preventive, long-term maintenance strategies. By combining smart technology with continuous training and a strong safety culture, we can create safe environments for both people and operations. Safety in maintenance goes beyond routines and checklists, it’s a vital part of building a resilient, sustainable industry where people come first.

At Underhåll 2026, you’ll gain in-depth knowledge of how to build safer workplaces, from physical safety and risk management to workplace technology and preventive maintenance. During Skyddsombudsdagarna, we’ll highlight today’s key safety issues and provide expert advice, live demonstrations, and real-world case studies.

FUTURE PRODUCTION

Shaping the smart industry today

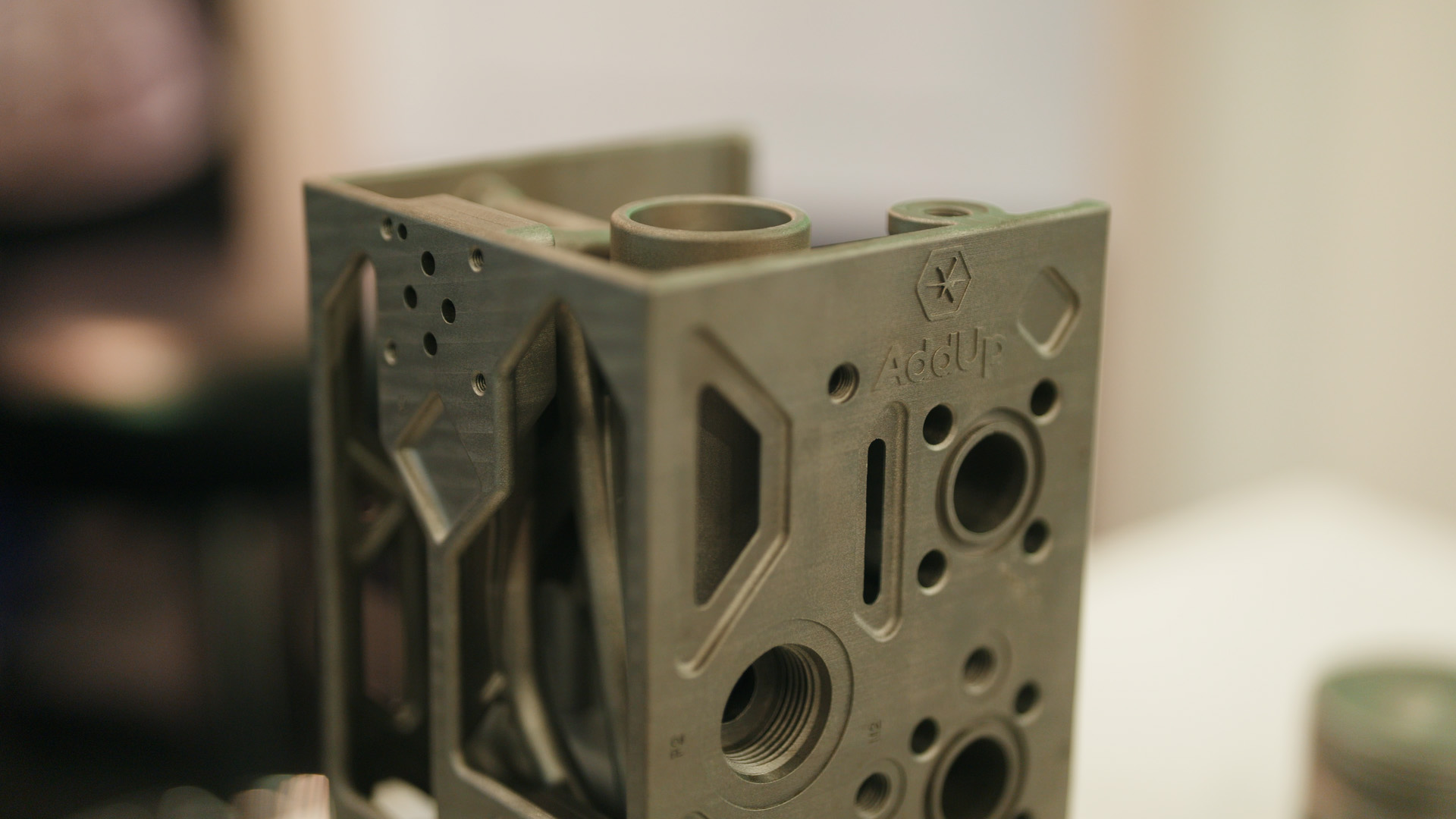

Industry is evolving at a rapid pace. The technology is already here, now it’s up to us to decide how we put it to work. Future production is about taking the next step in integrating smart systems, automation, AI, and robotics to create more efficient, flexible, and sustainable maintenance processes. But how do we secure the digital environments that increasingly connect our factories, machines, and business systems? The answer lies in collaboration, between people and machines, across departments, and between companies. By combining cutting-edge technology with human creativity and expertise, we can build agile business models, strengthen digital infrastructure, and optimize maintenance through smart and predictive tools. Collaboration, with maintenance at the center, is how we build the smart, safe, and sustainable industry of tomorrow.

At Underhåll 2026, you’ll gain valuable insights into the latest technologies in digitalization, automation, and predictive maintenance. Take part in seminars, workshops, and live demonstrations of innovative solutions, from digital security, additive manufacturing, and 3D printing to agile business models and smart maintenance strategies.

SKILLED MAINTENANCE

Securing growth through competence

Access to the right skills is one of the biggest challenges in maintenance today. To meet future demands and remain competitive, we need to take action now. How do we attract new talent while developing the expertise we already have? Can we build stronger bridges between education and industry, invest in upskilling, and create new, flexible models for learning? And how do we do all this while keeping pace with the rapid changes brought on by digitalization, automation, and AI? Together, we can shape an industry where maintenance competence is built, retained, and continuously developed.

At Underhåll 2026, you’ll learn more about how we cultivate and sustain a skilled maintenance workforce, through educational programs, hands-on workshops, and expert-led panel discussions. Join us as companies, educators, and industry leaders come together to share knowledge, spark collaboration, and strengthen the future of maintenance.